SSE, Wandsworth Riverside

Wandsworth Riverside Quarter, is an innovative district heating scheme, comprising six blocks with 550 residential units and a further 2,973 m2 of commercial space.

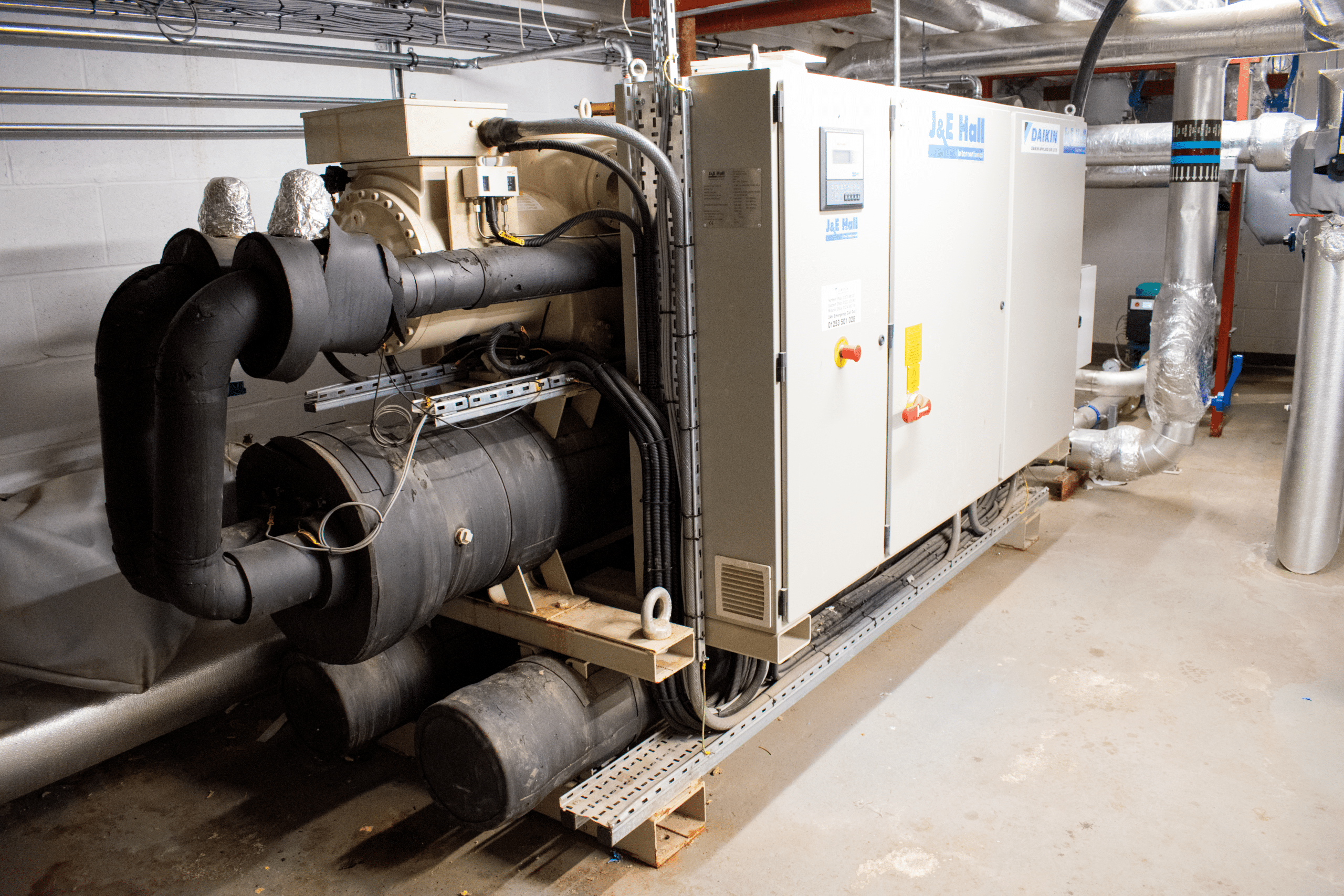

SSE worked with a geothermal/heat extraction expert to design an Aquifer Thermal Energy System (ATES) for this heating and cooling project. This is a highly innovative, integrated energy system which combines open loop ground source heat pumps in combination with gas Combined Heat and Power (CHP) to provide low carbon heat, hot water, cooling and electricity all under the control of SSE’s team.

SSE has worked with the client team throughout the construction process, bringing our many years’ experience, to ensure that commissioning of new phases can occur whilst the performance and integrity of the live network is protected. This is a complex exercise and a common challenge for multi-phase developments.

The scheme design was conceived in 2010 in response to the “London Plan” requirements for the generation of on-site energy in tandem with minimum standards for carbon abatement; fundamentally to address the need for the energy provision to the site to be ‘lean, clean and green’.

The technical solution identified was a relatively new approach for a heat and cooling network and hugely ambitious. The site uses open loop ground source heat pumps, drawing water from a series of four “cold” and four “warm” wells up to 100m deep under the site.

These run in combination with gas boilers and gas CHP to provide low carbon heat, hot water, cooling and electricity to this multi-phase development. Under a Joint Development Agreement with our client, Frasers Property Development (Frasers), SSE worked with the development team, engineering consultant, Hoare Lee, and geothermal heat abstraction expert, IFTech, to bring our expertise as a system operator and integrator.

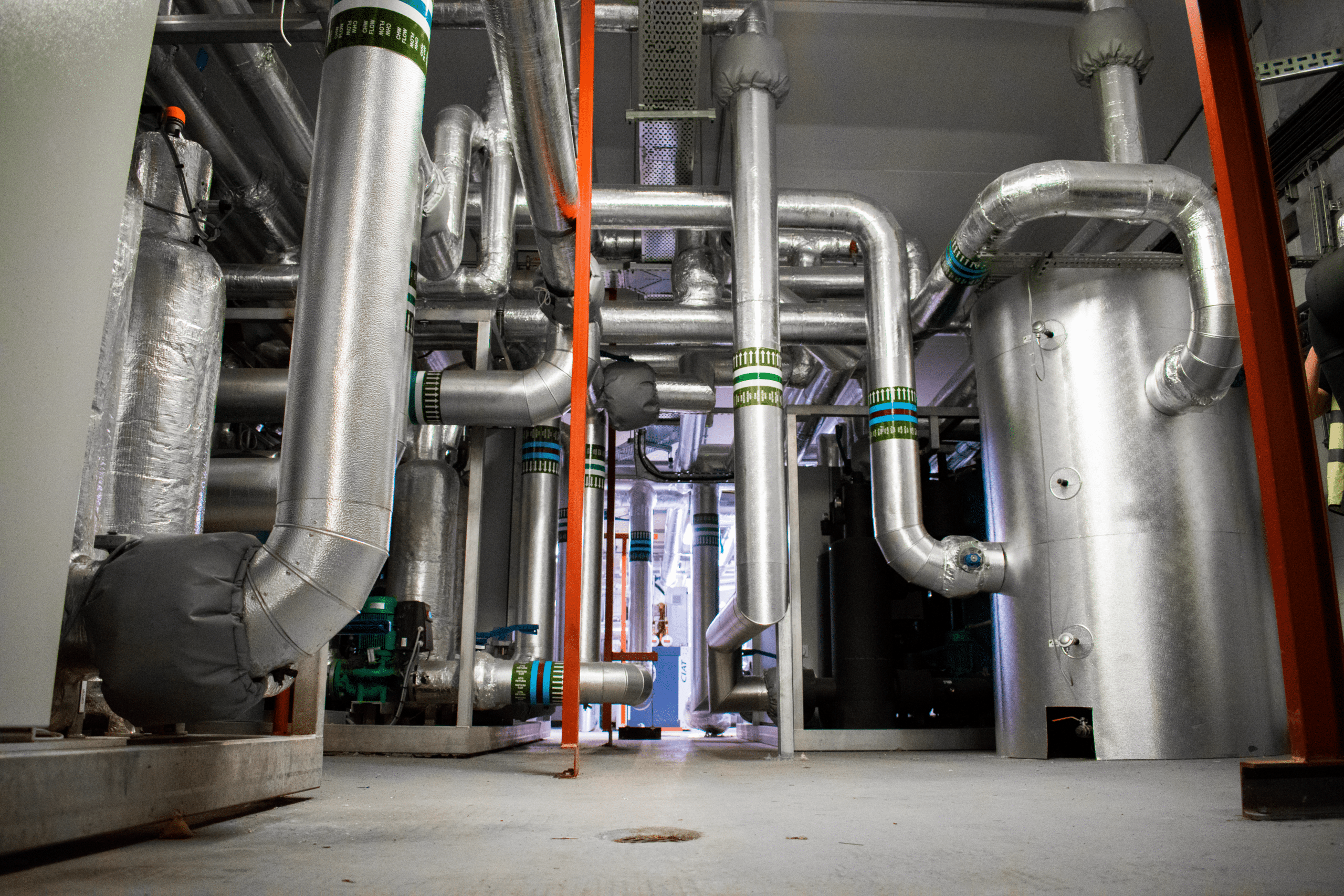

Complex systems such as this require careful design and commissioning and the operational challenges of extending the networks to each new phase of the development whilst maintaining efficient and reliable supplies to customers already connected, must be overcome.

Working closely with the client’s construction and commissioning teams, SSE provided commissioning specifications and operational protocols (which incorporated ongoing lessons learned) to help to ensure reliable supplies throughout. Once each phase was complete an exercise to re-optimise the whole system was undertaken.

Because of the phased development of the site, the hydraulic design of the networks need to have some excess capacity/capability installed. Usually this takes the form of large diameter low loss headers, that allow unstable and fluctuating conditions to prevail during energy use provision for the commissioning stages of future phases. During these periods, SSE manually intervenes to provide a stable network operating experience for connected customers.

The use of low loss headers on heating and cooling networks is contrary to textbook guidelines to achieve the intended network operating temperatures. SSE has successfully developed and deployed a BMS control strategy on another similar system it operates to achieve the widest possible cooling network operating temperatures whilst still retaining the low loss header.